Woodwatch

Posted

Contents

Wedding Anniversary No. 2

So… it’s yet another year since we got married! -woohoo-

Decided to venture and branch out into another realted skill tree, since I already got quite a good set of metalsmithing tools. That skill tree being…. watchmaking!

So in fear of all the pedantics out there, I am calling this watching case + dial making, with assembly.

Technically watch making would include cutting the tiny gears from metal sheets, milling the bridges and parts, designing your own movement etc. So, nope. that’s way too hardcore and I’m just going to purchase a cheap and trusty Miyota quartz movement.

Last year TP bought me a wooden watch as something that I’ve been eyeing for a while, so this year I wanted to try my hands on handcrafting a wooden watch for her.

Here goes!

Initial Design

So before I started, I wanted to look at some of TP’s existing watches and to figure out some important features of watches she likes.

- minimalistic dial design

- no second hand

- very small watch face

- non-chain link straps

- thin straps

So I landed on the following requirements for my eventual watch gift.

- 25mm outer diameter for the watch case

- Silver hard bangle for the wrist

- Hour hand + minute hand only

- Light-colored watch

Material Selection

Starting with the case, I’ve decided to go with maple, because it’s dense, closed grain and light colored. Being closed grain, it can be easily polished to a smooth finish.

For the watch dial I used a ¾” red oak dowel I had lying around, and this time, the open grain gave it a very nice texture.

esslinger.com is my go-to place for metalsmithing and watch making supplies.

For the movement I decided to go with the Miyota 2035 as it is small enough to fit within the 25mm case, and it’s also less than USD$5.00.

In retrospect I should have gone with the Miyota 2036 with a higher post, but more on that later

For the watch glass I went with 21mm, which was totally arbitrary, thinking I can leave a 2mm bezel around.

For the hands I picked a pair of simple diamond shaped silver hands.

For the crown it was also a tiny silver crown to match the hands.

Here’s the full buy list:

| Description | Parts Number | Qty |

|---|---|---|

| Watch Repair Parts Watch Dial Adhesives Package Of 100 | 80.122 | 1 |

| Watch Hand Remover Tool Compression Spring Style Watch Hand Puller | 59.0345 | 1 |

| Jewelers Screwdriver Set 9 Piece Phillips and Flat | 52.0929 1 | |

| Watch Hand Tool Press for Inserting Installing Wristwatch Hands | 59.0349 | 1 |

| Watchmakers Pithwood Buttons 10 pieces Assorted Sizes | 23.334 | 1 |

| Security Glue Ultraviolet Adhesive UV Glue for Glass and Watch Crystals 3mL | 12.228 | 1 |

| Watch Gasket Waterproof .60mm Thickness O-Ring Gaskets | 84.314.60 | 2 |

| Miyota/Citizen LTD 3 Hand Quartz Watch Movement 2035 Overall Height 4.7mm | 2035 | 2 |

| Quartz Dustproof Watch Crown Refills 2.75-3.5mm Diameter | 83.1280[1] | 2 |

| Watch Battery Energizer 377 And 376 Replacement Cell | 01377 | 1 |

| Round Sapphire Watch Crystal 1.0mm Thick | 201603-21.0 | 1 |

| Watch Parts Assorted Case Tube Mix 100 Various Sizes | 80.169 | 1 |

| Watch Parts Bestfit Movement Ring Refills Sold Per Piece | 80.033.12 | 2 |

| Watch Hands To Fit Minute Hand Hole Size .70mm And Hour Hand Hole Size 1.20mm | 86.213.4 | 2 |

| Diamond Burs Assortment of 20 | 19.125 | 1 |

Designing in Fusion360

The steps here are probably a bit reversed, as you should probably do this step first before purchasing the parts.

Items that can be sized more appropriately includes the watch glass, crown, hands and movement.

I was also design with the tools I currently have. The bit and brace set I have were in imperial sizes, so the closest that would work was ¾” which translates to ~19mm.

Played around with the renderer in Fusion 360 to get a rough idea of how the case would look with the maple wood.

The parts I modelled in this design were the watch case, watch glass, dial and movement. Mainly to see if the parts would fit together given the measaurements. You can easily find the drawings for the Miyota 2035 on the official website, for measurements such as recommended dial thickness, post sizes and position of the stem.

After putting everything together in Fusion 360, I liked what I see so on to the actual making!

Making the Case

Doing the Rough Cuts

I used a paper template I created in Illustrator to mark the case’s lines. Did not have access to a laser cutter so this is the next best thing.

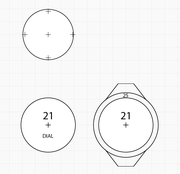

I had 2 shapes for the dial (top, left) with markers for the crystals and center holes. I had one shape for the case itself.

So I glued the template onto the maple block I had, and used my Dozuki saw to remove it as a block as a start. As usual, after getting used to sawing pine, the maple was hard as hell to get through.

I lost my glue stick, which I find the best for gluing templates onto the wood. I tried using my Titebond for this and it was way too wet, sticky and messy.